Surveillance of Analog Playback Devices

When large amounts of analog sound carriers need to be digitized, a significant improvement of quality surveillance as well as time savings can be achieved by the use of modern technology, especially when collections are recorded in standard formats and if they are of a mostly homogeneous technical quality.

Since analog playback devices are usually the most error-sensitive components in a digitization system, it is essential to supervise the quality of these devices. In order to achieve this, the Trusted Playback Service regularly receives quality metadata from a product called “Calibration-Inspector”, which is used to carry out the inspection of analog playback devices.

Calibration-Inspector is a fully automatic quality assessment system, developed in order to control and determine the quality of analog audio playback devices such as reel-to-reel machines, cassette tape players and turntables.

The system is shipping with specially manufactured test media, suited for the respective analog playback devices and capable of analyzing various machine specific measurement parameters such as frequency response, speed deviation, wow & flutter and total harmonic distortion, to name but a few.

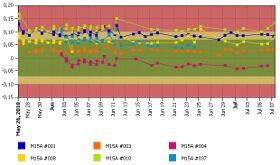

An interesting feature of this system is the possibility of a long-term evaluation and documentation of the results. By displaying the measurement results graphically over a longer period of time, subtle effects, as well as creeping deterioration, become visible and the comparison of different machines is made possible. Statistical evaluation of long-term data may provide insight into coherences which otherwise would not have become obvious. As an example, the diagram shows the speed deviation measured for six different reel-to-reel machines in percent over a time period of six weeks. The applied tolerances are displayed as different colored areas in the background of the diagram. The user can see at a glance if the chosen tolerances have been fulfilled.